07 Oct Boiler Parts: The Role of Burners in Industrial Boilers

Boiler parts come in a myriad of shapes and sizes, from small gauges to quite large burner assemblies. Today we look at the burner and its role in the function of commercial boilers.

Industrial boilers are systems that convert chemical energy (from fuels like natural gas, fuel oil, biomass, etc.) into heat, which is transferred to water to produce steam or hot water. The burner is the heart of that process: it’s the component where fuel and air are mixed, ignited, and where combustion takes place, producing the flame that provides heat to the boiler’s furnace or firebox. The effectiveness, safety, emissions, and efficiency of the boiler all depend critically on how well the burner works.

Some key functions of a burner include:

- Fuel Atomization or Fuel-Air Mixing

For liquid or heavy fuels, the burner must properly atomize the fuel so that tiny droplets are created, which can mix well with air and combust completely. For gaseous fuels, there often needs to be fine mixing and sometimes premixing. Proper mixing is essential for stable flame, high efficiency, and low emissions. - Ignition and Flame Stabilization

The burner must reliably ignite the fuel/air mix (via pilots, spark ignition, or other systems) and maintain flame stability across operating ranges — from low firing/load to high demand. Flame shape and location are also important to ensure the flame contacts the furnace surfaces in the proper way (for good heat transfer) and doesn’t impinge destructively. - Control of Air / Fuel Ratio & Turndown

As boilers run under different loads, the burner must adjust fuel flow and air flow to maintain efficient combustion. Turndown ratio — the range between minimum firing (low load) and maximum firing — is important. A burner that can handle a wide turndown (e.g., 4:1, 10:1) helps avoid frequent cycling, improves responsiveness, and reduces thermal stress. - Emission Control

Burners play a major role in emissions of NOₓ, carbon monoxide (CO), unburned hydrocarbons, and smoke or soot. Advanced burner designs include features like flue gas recirculation (FGR), staged combustion, low‐NOₓ head designs, oxygen trim, etc. These reduce the flame temperature or alter combustion dynamics to limit NOₓ and other harmful byproducts. - Safety Functions

Burners include a number of safety features and are subject to burner management systems (BMS). These might include flame detection or flame scanners, flame failure shutdowns, interlocks, purging cycles, safety shutdown valves, and controls to prevent unsafe fuel accumulation. - Efficiency & Heat Transfer

The burner’s design, with its mixing, flame shape, and combustion quality, affects how uniformly heat is delivered in the furnace, how much radiation and convection heat transfer occurs, and how clean the combustion products are (because soot or incomplete combustion can reduce heat transfer surfaces and waste fuel).

Limpsfield Burners — Features & Capabilities

“Limpsfield Combustion Engineering” is a manufacturer of industrial and commercial burners with some notable characteristics. Here are highlights regarding what Limpsfield burners offer, how they are designed, and what makes them stand out:

- Range and Fuel Flexibility: Limpsfield burners are built for a wide range of outputs (from relatively small capacity to very large, up to ~62 MW) and can handle multiple fuel types: natural gas, diesel or #2 oil, heavier fuel oils, waste oils, bio-gases, animal and fish fats/oils, even hydrogen in many cases. This dual or multi-fuel flexibility makes them suitable for retrofits, mixed fuel operations, or switching fuels as supply or regulation demands.

- Forced Draft Design: Their burners are forced draft — meaning air is actively drawn/pushed via a fan and distributed at the burner head so that combustion air supply is well controlled. This ensures the flame geometry and stability remain consistent across the firing range.

- Low O₂ and Low CO Emissions, Low NOₓ Options: Limpsfield burners are designed to operate with low excess oxygen — often achieving below 3% O₂ (when firing gas) and with CO emissions also very low. Their design also supports low NOₓ emissions, especially with features like flue gas recirculation (FGR). This helps meet environmental regulations and can reduce fuel waste.

- High Turndown Ratios: Their LC and LP burner series offer high turndown (between ~4:1 up to 10:1) so they can adjust from low fire to high fire while maintaining good control of combustion, flame stability, and emissions.

- Design for Maintenance & Access: Several features are intended to make maintenance easier: large viewing ports to observe flame, burner heads and diffusers made of stainless steel or other durable materials, parts accessible without removing the entire burner from the boiler front, split head or spider head designs for adjusting gas head/diffuser positions, damper bearings, etc. All this helps with service, inspection, and adjustment.

- Control Systems: Limpsfield supplies control panels and systems (often with Autoflame or analogous modulation controls) to manage fuel/air ratio, burner sequencing, flame detection, etc. These control systems help operators optimize performance, maintain safety, and adjust to changing loads or fuel types.

- Performance Gains: In various case studies, Limpsfield burner installations have reported significant fuel savings (often 10–35%) and emissions reductions when replacing older or less efficient burner systems.

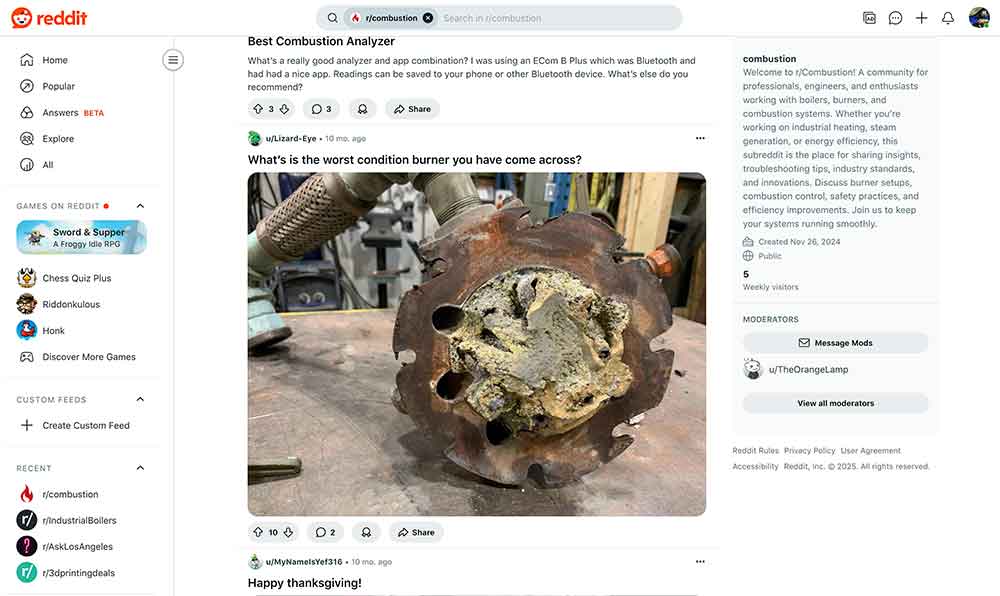

What Happens When Burner Assemblies Are Neglected — Potential Problems

Burner assemblies are complex systems, combining mechanical, electrical, control, and combustion subsystems. Neglecting proper maintenance can lead to a wide range of performance degradation, safety risks, operational problems, and regulatory or environmental issues. Below are some of the most common issues:

- Incomplete Combustion

- If fuel nozzles or atomizers become clogged or worn, they may spray unevenly or poorly, leading to larger or irregular fuel droplets that don’t burn completely.

- Air supply paths (dampers, fan, air registers) may get blocked, dirty, or misaligned, so the air/fuel ratio drifts.

- Dirty flame detectors or faulty flame scanners can misinterpret flame stability.

Consequences: increased emissions of CO, unburned hydrocarbons, soot; reduced thermal efficiency; possible buildup of soot or carbon deposits in boiler passages.

- Reduced Efficiency and Higher Fuel Costs

- Scaling and soot on heat transfer surfaces reduce heat transfer, forcing more fuel to maintain output. Even a small layer of scale or soot can degrade efficiency noticeably.

- Losses in turndown efficiency: if the burner cannot properly modulate to low load, the boiler may cycle frequently (turn on/off), which wastes fuel, increases wear, and increases thermal stress.

- Safety Risks

- A crucial issue is flame failure or flame instability. If the flame goes out but the fuel continues (or there is delayed ignition), unburned fuel can accumulate, leading to explosion risk. Flame sensors, purge cycles, and gas/fuel shutoff valves must operate reliably.

- Gas leaks from valves or piping that aren’t maintained or inspected can lead to fire or explosion.

- Overheating or hot spots if flame impinges on surfaces due to misalignment of burner head or damaged refractory. This can lead to structural damage or failure of the furnace or burner housing.

- Emissions & Regulatory Non-Compliance

- When combustion is inefficient, NOₓ, CO, particulate, and other regulated emissions may exceed permit limits. This can lead to fines, shutdowns, or mandatory retrofits.

- Drift in oxygen levels or air flow can cause excess O₂ (wasting heat) or too little (risking CO or soot). Emissions limits (NOₓ especially) often require keeping flame and burner design within certain parameters.

- Mechanical Wear and Component Failure

- Burners have many components subject to wear: fan motors, bearings, dampers, linkages, nozzle/atomizer components, igniters, flame sensors, control valves, refractory lining, etc. If neglected, these parts degrade, leading to misfires, leaks, ignition delays, or inability to modulate properly.

- For example, electrodes for ignition can crack or erode; burner heads might warp; seals or gaskets may leak; air dampers may bind. These failures reduce reliability and may require expensive emergency repairs.

- Operational Downtime & Maintenance Costs

- Unscheduled shutdowns result in lost production, reduced output, potential damage to other equipment.

- When problems escalate (for example, safety controls fail, or flame path is compromised), the cost to repair is much higher than regular maintenance.

- Heat Transfer and Pressure Vessel Stress Issues

- Poor burner performance can lead to uneven heating inside the boiler, thermal gradients that stress metal, leading to cracks or fatigue.

- If burner flame shape or position changes (e.g., flame impingement on parts not designed for direct flame), it can damage boiler tubes, refractory, or boiler walls.

How Neglect Typically Unfolds in Practice

To understand how these problems develop, here’s a typical scenario of how neglect in burner maintenance can escalate:

- Over time, air filters, dampers, and combustion air intakes collect dust, debris, or are blocked. The forced draft fan or blower may slowly lose efficiency or have leaks.

- The nozzle or atomizer starts to wear or accumulate coke or varnish residues, causing uneven spray or poor atomization.

- Flame detection devices (UV sensors, flame rods) become dirty or misaligned; occasionally flame “shadows” or extinction events occur, which may trigger safety shutdowns.

- Slight drift in fuel or air valve calibration causes either lean or rich combustion; say, the burner runs slightly rich, producing more CO/smoke, or too lean, losing efficiency.

- Discoloration or soot on furnace surfaces reduces heat transfer. Refractory might degrade or crack if flame impinges where it shouldn’t.

- Regular checks are skipped or postponed due to operational pressures (e.g., “try to avoid shutting down the boiler,” or “we’ll check during the next scheduled outage”).

- Because safety and emissions inspections are sometimes at fixed intervals (or periodic), deficiencies may go unnoticed until they cause violations, forced shutdowns, or catastrophic damage (e.g., cracked firebox, burnt tubes, or worse).

Best Practices & Preventive Maintenance for Burners

To avoid the problems above, industrial facilities should follow best practices for burner maintenance. Some of these include:

- Routine inspection and cleaning of the burner components: nozzles / atomizers, diffusers, fuel valves, flame sensors, ignition electrodes.

- Combustion tuning: regular checks of fuel/air ratio, oxygen content in flue gas, carbon monoxide levels, and adjusting dampers and fuel delivery to match load conditions.

- Monitoring flame stability: use of flame scanners or UV sensors, ensuring ignition reliability, confirming flame shape and contact with furnace surfaces.

- Check fan/blower performance, ensure dampers move freely, air passages are clean, fans are balanced, bearings are lubricated.

- Inspect refractory lining, burner head alignment, burners’ mounting, seals and gaskets to avoid leaks around the burner.

- Ensure safety interlocks and purge cycles are working: flame failure detection, flame safeguard, gas valve shut-off, purging of fuel lines in startup/shutdown.

- Maintain control systems: calibration of sensors, valves, control panels, ensure software/firmware is up to date.

- Document performance: record the oxygen levels, CO, NOₓ emissions over time, fuel consumption, observe any trends.

- Use OEM or high-quality replacement parts: nozzles, sensors, valves matched to design tolerances — mismatched or inferior parts often lead to poor performance or accelerated wear.

- Scheduled overhauls: at certain operating hours, major checks, replace key wear items before failure.

How Limpsfield Burners Help Mitigate Common Problems

Given the features of Limpsfield burners, many of the issues that arise in neglected burner assemblies are mitigated:

- Because they have good access to critical components (e.g., burner head, diffuser, viewing port), maintenance and inspection are easier and quicker. This reduces downtime for inspection or minor repairs.

- The forced draft design and stable mixing ensure that flame geometry remains stable, which helps prevent flame impingement, hot spots, or uneven heating, even across load swings.

- The low O₂ design, and nozzle / diffuser adjustments, allow more consistent combustion and easier compliance with emissions standards—even as fuel types or ambient conditions change.

- High turndown capability means the burner can operate safely and efficiently at low loads, avoiding the inefficiency or wear that comes with frequent shutdowns or cycling.

- The control systems (Autoflame etc.) used by Limpsfield allow precise regulation, monitoring, and adjustment, which helps catch drift before it becomes serious.

Conclusion

Burners are central to the performance, safety, efficiency, and regulatory compliance of industrial boilers. A high-quality burner, properly designed and maintained, delivers stable flame, clean combustion, fuel savings, low emissions, and safe operation. Limpsfield burners are a strong example of modern burner technology: flexible fuel options, strong control over emissions (low O₂, low CO, low NOₓ), good access for maintenance, high turndown ratios, and robust design & controls.

Neglecting burner maintenance, in contrast, can lead to a cascade of issues: reduced efficiency, higher fuel costs, unsafe operating conditions, emission violations, and ultimately downtime and expensive repairs. For any facility relying on industrial boilers—factories, hospitals, district heating, food processing, or institutional campuses—investing in regular burner inspection, tuning, and use of high-quality parts is not just good practice—it’s essential.

Sorry, the comment form is closed at this time.