Introduction to Feedwater Systems

Feedwater systems of industrial boilers in Los Angeles are essential components of any boiler operation, whether it’s in a residential, commercial, or industrial setting. They supply water to boilers to produce steam or hot water, which is then used for heating, power generation, or various industrial processes. A well-designed feedwater system ensures the boiler operates efficiently, reliably, and safely. This comprehensive guide will explore the different aspects of feedwater systems, including their components, operation, types, and importance, as well as maintenance practices and modern innovations.

Los Angeles boiler company feedwater system

Components of Feedwater Systems

Feedwater systems consist of various components that work together to ensure the delivery of water to the boiler at the right pressure, temperature, and quality. Understanding these components is crucial for efficient system operation and maintenance.

- Feedwater Pumps

Feedwater pumps are the heart of the feedwater system. They move water from the feedwater tank or deaerator to the boiler. These pumps must be capable of overcoming the boiler pressure to ensure a consistent flow of water.

- Centrifugal Pumps: Commonly used in feedwater systems, these pumps use rotational energy from an impeller to increase water pressure.

- Positive Displacement Pumps: These pumps move water by trapping a fixed amount and forcing (displacing) it into the discharge pipe. They are used in high-pressure applications.

- Feedwater Heaters

Feedwater heaters improve the thermal efficiency of the boiler by preheating the feedwater before it enters the boiler. This reduces the energy required to heat the water to its boiling point, thereby saving fuel and improving efficiency.

- Open Feedwater Heaters: These heaters mix the feedwater with steam to heat it.

- Closed Feedwater Heaters: In these heaters, steam passes through a tube bundle, and feedwater flows around the tubes, getting heated indirectly.

- Deaerators

Deaerators are critical for removing dissolved gases such as oxygen and carbon dioxide from the feedwater. These gases can cause corrosion in the boiler and steam system. Deaerators use steam to heat the feedwater and strip out the dissolved gases, which are then vented to the atmosphere.

- Spray Type Deaerators: These units spray feedwater into a steam atmosphere, promoting the release of dissolved gases.

- Tray Type Deaerators: In these units, water cascades over a series of trays in a steam atmosphere, enhancing the contact between water and steam for effective gas removal.

- Economizers

Economizers are heat exchangers that capture waste heat from the boiler flue gases and use it to preheat the feedwater. This process improves boiler efficiency by recovering energy that would otherwise be lost.

- Control Valves and Regulators

Control valves and regulators ensure that the feedwater is delivered to the boiler at the correct pressure and flow rate. These components are essential for maintaining stable boiler operation and preventing water hammer and other issues.

- Pressure Reducing Valves: These valves control the pressure of the feedwater entering the boiler.

- Flow Control Valves: These valves regulate the flow rate of the feedwater to match the boiler's requirements.

- Water Treatment Equipment

Proper water treatment is vital for preventing scale, corrosion, and other issues that can damage the boiler and reduce its efficiency. Water treatment equipment can include:

- Softening Systems: These systems remove hardness ions (calcium and magnesium) from the water.

- Chemical Feed Systems: These systems add chemicals to the feedwater to control pH, oxygen levels, and other parameters.

- Filtration Systems: These systems remove particulates and impurities from the feedwater.

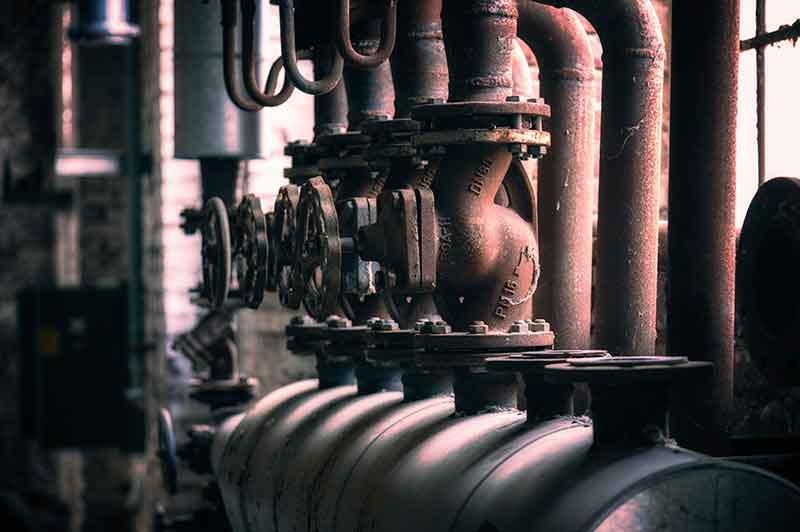

Commercial boiler pipes with feedwater system in Los Angeles factory

Operation of Feedwater Systems

The operation of a feedwater system involves several key steps, from water intake and treatment to delivery to the boiler. Understanding these steps is essential for efficient and reliable system performance.

- Water Intake and Treatment

The first step in the feedwater system operation is the intake of raw water, which is then treated to remove impurities and adjust its chemical composition. This treatment process can involve:

- Filtration: Removing particulates and suspended solids.

- Softening: Removing hardness ions to prevent scale formation.

- Deaeration: Removing dissolved gases to prevent corrosion.

- Chemical Treatment: Adding chemicals to control pH, oxygen levels, and other parameters.

- Preheating

After treatment, the feedwater is often preheated using feedwater heaters or economizers. Preheating improves boiler efficiency by reducing the energy required to heat the water to its boiling point.

- Pumping

Feedwater pumps move the treated and preheated water to the boiler. The pumps must be capable of overcoming the boiler pressure and maintaining a consistent flow rate to ensure stable boiler operation.

- Control and Monitoring

Control valves and regulators ensure that the feedwater is delivered to the boiler at the correct pressure and flow rate. Monitoring systems track key parameters such as water temperature, pressure, and chemical composition to ensure optimal performance and prevent issues.

- Delivery to the Boiler

The final step is the delivery of the feedwater to the boiler. The water enters the boiler, where it is heated to produce steam or hot water for various applications.

Types of Feedwater Systems

Feedwater systems can be categorized based on their design, application, and the type of boiler they serve. Understanding these types helps in selecting the right system for a specific application.

- Open Feedwater Systems

Open feedwater systems are typically used in low-pressure boiler applications. In these systems, the feedwater tank is open to the atmosphere, and the feedwater is gravity-fed to the boiler. These systems are simple and cost-effective but may not be suitable for high-pressure applications.

- Closed Feedwater Systems

Closed feedwater systems are used in high-pressure boiler applications. In these systems, the feedwater tank is closed and pressurized to match the boiler pressure. This design helps prevent the ingress of air and other contaminants, improving system efficiency and reliability.

- Deaerating Feedwater Systems

Deaerating feedwater systems are designed to remove dissolved gases from the feedwater to prevent corrosion. These systems use deaerators to heat the feedwater and strip out gases such as oxygen and carbon dioxide. Deaerating feedwater systems are essential for high-pressure and high-temperature applications where corrosion is a significant concern.

- Economizer Feedwater Systems

Economizer feedwater systems incorporate economizers to capture waste heat from the boiler flue gases and use it to preheat the feedwater. These systems improve boiler efficiency by recovering energy that would otherwise be lost. Economizer feedwater systems are commonly used in large industrial and commercial applications.

Importance of Feedwater Systems

Feedwater systems are crucial for the efficient, reliable, and safe operation of boilers. Their importance can be understood by examining their impact on various aspects of boiler performance and operation.

- Efficiency

A well-designed and properly maintained feedwater system improves boiler efficiency by ensuring that the feedwater is delivered at the correct temperature, pressure, and quality. Preheating the feedwater using economizers or feedwater heaters reduces the energy required to heat the water to its boiling point, saving fuel and reducing operating costs.

- Reliability

Feedwater systems are essential for the reliable operation of boilers. Properly treated and conditioned feedwater prevents issues such as scale formation, corrosion, and fouling, which can cause boiler failures and downtime. Regular maintenance and monitoring of feedwater systems help detect and address issues before they become critical.

- Safety

Safety is a critical concern in boiler operation, and feedwater systems play a vital role in ensuring safe operation. Proper water treatment and deaeration prevent corrosion and reduce the risk of boiler explosions and other hazards. Control valves and regulators maintain stable pressure and flow rates, preventing water hammer and other issues.

- Environmental Impact

Efficient feedwater systems help reduce the environmental impact of boiler operation. By improving boiler efficiency and reducing fuel consumption, these systems help lower greenhouse gas emissions and other pollutants. Proper water treatment also minimizes the discharge of harmful chemicals and contaminants into the environment.

Boiler room in Los Angeles, CA

Maintenance of Feedwater Systems

Regular maintenance is essential for the efficient and reliable operation of feedwater systems. Proper maintenance practices help prevent issues, extend the lifespan of the system, and ensure compliance with safety and environmental regulations.

- Routine Inspections

Routine inspections involve checking various components of the feedwater system for signs of wear, corrosion, leaks, or other issues. Key areas to inspect include:

- Feedwater Pumps: Check for proper operation, lubrication, and any signs of wear or damage.

- Feedwater Heaters: Inspect for scale buildup, leaks, and proper operation.

- Deaerators: Check for proper deaeration, inspect vents and trays for blockages or damage.

- Control Valves and Regulators: Test and calibrate controls, check for leaks and proper operation.

- Cleaning

Regular cleaning of feedwater system components is essential to maintain efficiency and prevent damage. This includes:

- Feedwater Heaters: Remove scale and deposits from the heat exchange surfaces to improve heat transfer.

- Deaerators: Clean vents, trays, and other components to ensure effective gas removal.

- Filters: Replace or clean filters regularly to remove particulates and impurities from the feedwater.

- Water Treatment

Proper water treatment is crucial for preventing scale, corrosion, and other issues. This involves:

- Regular Testing: Test feedwater regularly to monitor pH, hardness, dissolved gases, and other parameters.

- Chemical Treatment: Adjust chemical dosages based on water quality testing results to maintain optimal conditions.

- Blowdown: Perform regular blowdown to remove impurities and maintain water quality.

- Preventive Maintenance

Preventive maintenance involves regularly scheduled tasks to keep the feedwater system in optimal condition. This includes:

- Lubrication: Lubricate moving parts such as pumps and valves to ensure smooth operation.

- Calibration: Calibrate control valves, regulators, and sensors to ensure accurate operation.

- Testing: Test safety devices, controls, and monitoring systems to ensure they function correctly.

- Replacement: Replace worn or damaged components before they fail to prevent system downtime.

Modern Innovations in Feedwater Systems

Advancements in technology have led to significant innovations in feedwater systems, improving their efficiency, performance, and environmental impact.

- Smart Controls and Monitoring

Smart controls and monitoring systems use advanced sensors and algorithms to optimize feedwater system operation. These systems can adjust parameters in real-time, monitor performance, and detect issues before they become critical. Smart controls improve efficiency, reduce downtime, and enhance safety.

- Advanced Water Treatment Technologies

Modern water treatment technologies offer more effective and efficient solutions for treating feedwater. These include:

- Membrane Filtration: Advanced filtration technologies such as reverse osmosis (RO) and nanofiltration (NF) provide high-efficiency removal of impurities and dissolved gases.

- Electrodeionization (EDI): EDI is an advanced water treatment process that uses electricity, ion exchange membranes, and resin to remove ions from water, producing high-purity feedwater.

- Advanced Chemical Treatment: New chemical formulations and dosing technologies provide more effective control of pH, hardness, and other parameters.

- Energy Recovery Systems

Energy recovery systems capture waste heat from various processes and use it to preheat the feedwater, improving overall system efficiency. These systems can include:

- Heat Recovery Steam Generators (HRSG): HRSGs capture waste heat from gas turbines and other processes to generate steam or preheat feedwater.

- Waste Heat Boilers: These boilers use waste heat from industrial processes to generate steam or hot water for feedwater preheating.

- Renewable Energy Integration

Integrating renewable energy sources such as solar thermal and biomass with feedwater systems can reduce reliance on fossil fuels and lower greenhouse gas emissions. Solar thermal systems can preheat feedwater using solar energy, while biomass boilers can use renewable organic materials as fuel.

Importance of Feedwater Systems in Various Industries

Feedwater systems are crucial for the efficient and reliable operation of boilers in various industries. Their importance can be understood by examining their impact on different sectors.

- Power Generation

In the power generation industry, feedwater systems are essential for the efficient and reliable operation of steam turbines and boilers. Proper feedwater treatment and conditioning prevent issues such as scale and corrosion, which can reduce efficiency and cause costly downtime. Advanced feedwater systems with energy recovery and smart controls help power plants achieve higher efficiency and lower emissions.

- Manufacturing and Industrial Processes

In manufacturing and industrial processes, feedwater systems provide the necessary steam and hot water for various applications, including process heating, cleaning, and sterilization. Efficient feedwater systems help improve productivity, reduce operating costs, and ensure compliance with safety and environmental regulations.

- Healthcare

In healthcare facilities, feedwater systems are essential for providing hot water and steam for heating, sterilization, and other critical processes. Proper water treatment and conditioning prevent issues such as scale and corrosion, ensuring reliable operation and patient safety. Advanced feedwater systems with smart controls and monitoring help healthcare facilities achieve higher efficiency and lower costs.

- Hospitality

In the hospitality industry, feedwater systems provide hot water and steam for guest rooms, kitchens, laundry facilities, and spa services. Efficient feedwater systems ensure guest comfort and satisfaction while reducing operating costs and environmental impact. Modern feedwater systems with energy recovery and renewable energy integration help hotels and resorts achieve higher efficiency and sustainability.

- Food and Beverage

In the food and beverage industry, feedwater systems are used for process heating, cleaning, and sterilization. Proper water treatment and conditioning are crucial for ensuring product quality and safety. Efficient feedwater systems help improve productivity, reduce operating costs, and ensure compliance with safety and environmental regulations.

Conclusion

Feedwater systems are essential for the efficient, reliable, and safe operation of boilers in various industries. Understanding the different components, types, operation, and maintenance practices of feedwater systems is crucial for selecting the right system and ensuring optimal performance. Modern innovations in feedwater systems, such as smart controls, advanced water treatment technologies, energy recovery systems, and renewable energy integration, offer significant improvements in efficiency, performance, and environmental impact. Whether in power generation, manufacturing, healthcare, hospitality, or food and beverage, feedwater systems play a critical role in maintaining productivity, safety, and sustainability.