23 Jan The Top 5 Components and Accessories for Improving Boiler Performance

There are a number of boiler components and accessories that are vital in maintaining the performance and efficiency of industrial boilers. These various parts of your system help optimize the boiler’s functioning, resulting in cost savings and improved overall performance. Let’s take a look at the top 5 components and accessories for industrial boiler performance, why they are important, and the potential return on investment (ROI) that they can provide.

Stack Economizers

Stack economizers are devices that are installed in the flue gas exhaust system of a boiler. They work by recovering waste heat from the flue gases and using it to preheat the incoming feed water. This results in a reduction in fuel consumption, and an improvement in overall boiler efficiency of up to 4-5%, depending on your operating temperature.

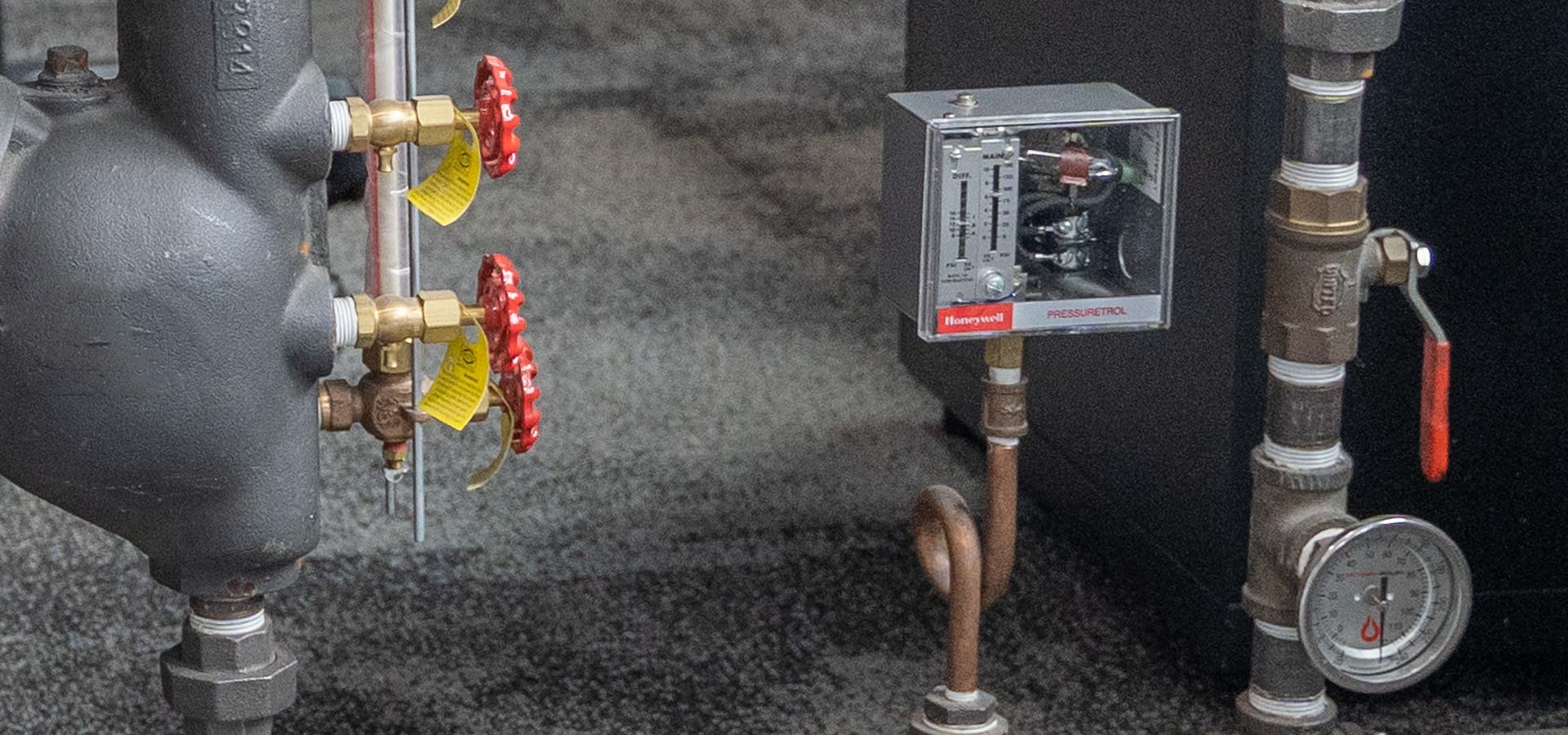

Blowdown Separators

Blowdown separators are used to separate and remove impurities that build up in the boiler over time. These impurities can reduce the efficiency of the boiler and increase the risk of corrosion. By removing these impurities, blowdown separators help to improve the performance of the boiler and extend its lifespan.

Insulation

Insulation allows you to save energy by reducing heat loss from the piping, valves, and other equipment surfaces. It also has the secondary benefit of making the surrounding work environment more comfortable, so reducing this heat loss can also reduce the amount of energy you use to cool the surrounding environment. Insulation also has safety benefits by reducing the outer surface temperature of the piping, which lessens the risk of burns.

Condensate Return Systems

Condensate return systems are designed to recover condensate that is produced during the steam generation process. This condensate is then used to preheat the incoming water, which results in a reduction in fuel consumption.

Automatic Blowdown Control Systems

Automatic blowdown control systems are designed to automatically control the blowdown process of a boiler. This helps to optimize the amount of water discharged from the boiler as it relates to the number of solids. This can result in a reduction in overall fuel consumption since you won’t have to consume and heat as much water. According to the U.S. Department of Energy, these savings can pay for the investment in an automatic blowdown control system within 1-3 years.

McKenna Boiler Are Experts in Accessories and Maintenance

Boiler accessories can improve the efficiency and safety of your boiler, as well as reduce energy costs and emissions. Stack economizers, blowdown separators, insulation, condensate return systems, and automatic blowdown control systems are some of the top accessories to improve the efficiency of industrial boilers. The ROI of these accessories can be significant, with some systems able to pay for themselves in as little as 1-3 years. Contact us today to speak to a member of our team to discuss your needs.

Sorry, the comment form is closed at this time.